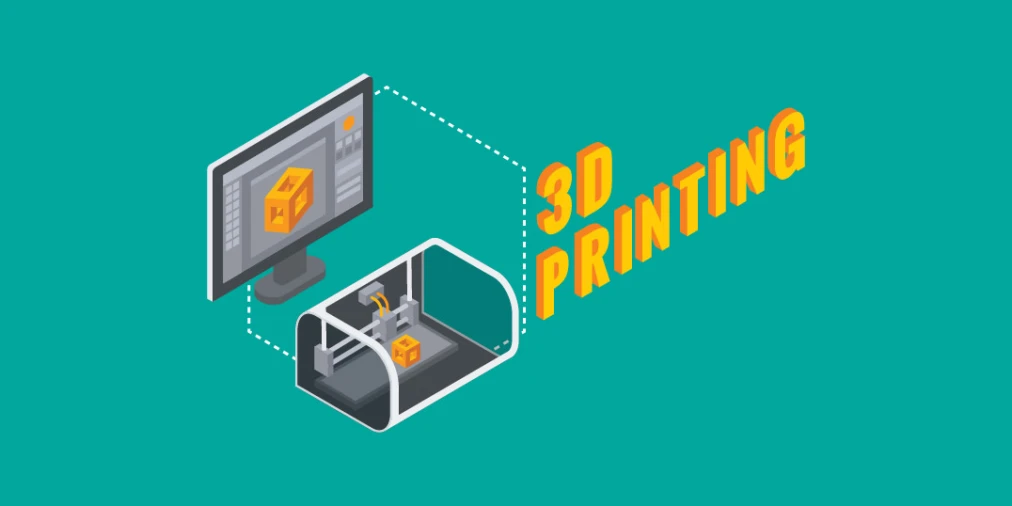

How it works

Firstly, let’s try and define 3D printing and explain – without jargon – how the magic happens. Things aren’t a million miles away from the standard 2D printing process in that the user sends a digital file (albeit this time made using 3D software) to the printer. 3D printers differ in that they use a special type of ‘ink’ called filaments, which can be made up of just about anything (paper, metal, glass… you name it). The printer then goes through many cycles to create a layered, physical object.

3D printing has revolutionised the way that items are made. We can print bespoke human body parts and even food nowadays (yes, seriously), and the ability to make just about whatever we want isn’t the only benefit.

The accuracy offered by 3D printing is unparalleled – we can create intricate, precise designs on demand, and with little to no wastage. The whole process saves on both cost and time. What’s more, if by chance we’ve made a mistake as part of the design process, we needn’t go back to square one – we can simply make tweaks to the original file and go again. When it comes to product development, making use of 3D printing is a no-brainer.