The Science Behind Vantablack

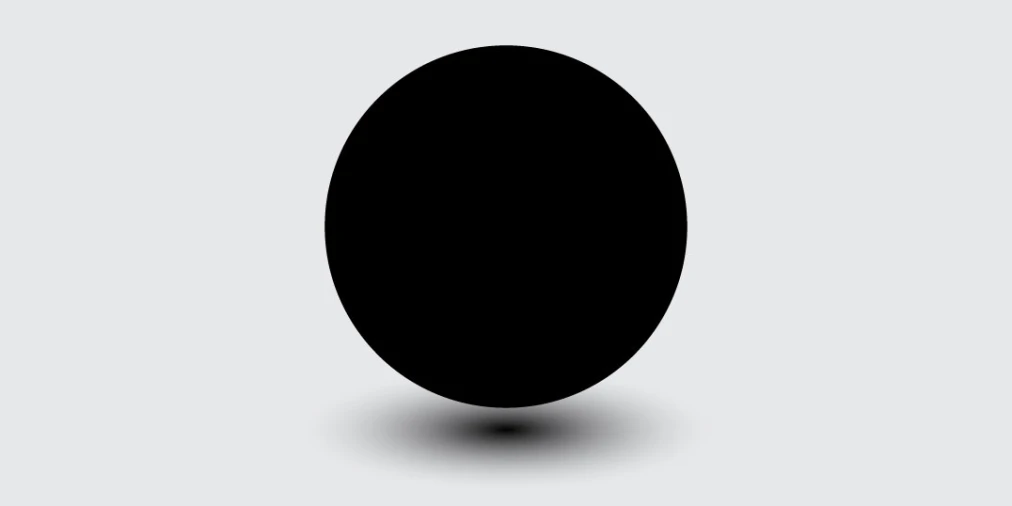

Firstly, let’s take a look how it works (the clue is in the name). The acronym VANTA stands for ‘vertically aligned nanotube arrays’ – if that phrase seems a little overawing, allow us to elaborate: Vantablack is more of a coating than a colour. It is made up of a thin film of carbon nanotubes which are applied to an object in a reactor chamber. Light is absorbed (and trapped) within the nanotubes, with any stray light rays also being absorbed by neighbouring tubes.

In terms of application, there are a few hurdles to overcome. Standard Vantablack can only be applied to materials at 400C, though Surrey NanoSystems did announce a spray-on version of the product, which blocks 99.8% of light, in 2017 (though even this version requires conditions of 100C to stand a chance of being applied successfully). As a result of such high thermal requirements, any materials with a lower melting point will have to settle for being painted boring old standard black. And even if the optimum temperature is achieved, it’s still very difficult to successfully apply Vantablack to, well… anything. All of this means that Vantablack is extremely expensive as a result (the average cost of a single sample is circa £300).

Since Vantablack is a coating, it’s technically not a colour at all, a classification which bears semblance to the age-old truth that standard black is not a colour either, but rather ‘the absence of visible light’. This doesn’t mean that black (or Vantablack for that matter) is any less relevant when it comes to colour theory and design rationale, though – which leads us to the million-pound question: how do the two compare visually?